Dry electrode fabrication paper published in Advanced Materials Technologies

Ryan Kaveh and Natalie Tetreault’s paper from Muller and Arias groups presenting a rapid fabrication method for low impedance, 3D dry electrodes has been published in Advanced Materials Technologies. Read it here:

R. Kaveh*, N. Tetreault*, K. Gopalan, J. Maravilla, M. Lustig, R. Muller, A. C. Arias, “Rapid Fabrication of Low Impedance, 3D Dry Electrodes for Physiological Sensing,” Advanced Materials Technologies, 2200342, May 2022.

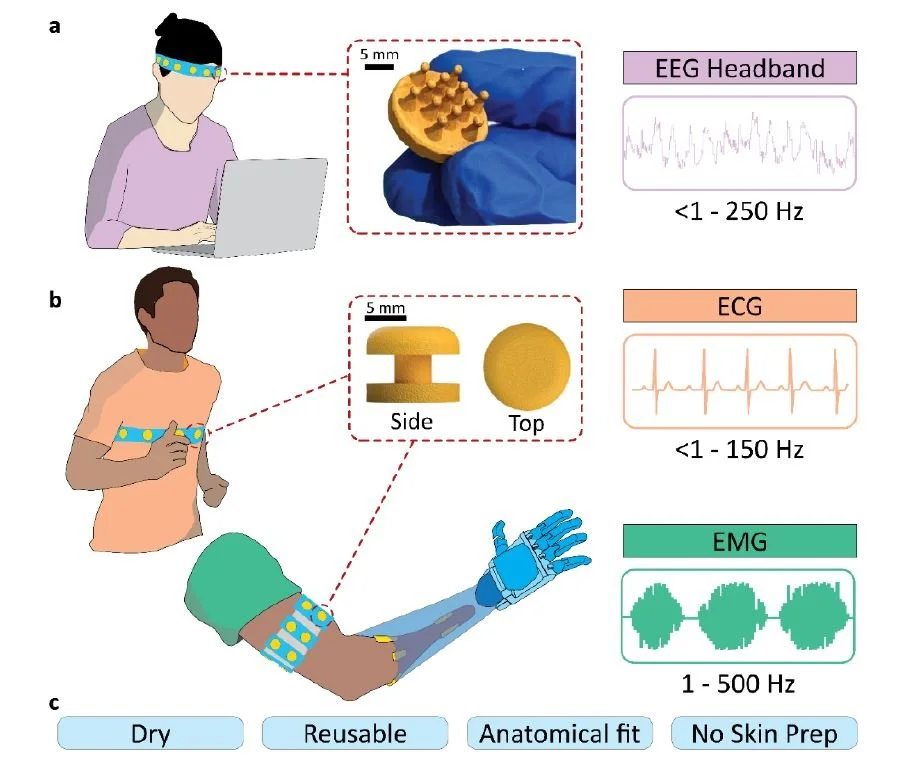

Medical electrophysiological sensors that can study the body and diagnose diseases depend on consistently low impedance electrode–skin interfaces. Clinical-standard wet electrodes use hydrogels and skin abrasion to improve the interface and thus the recorded signal quality. These electrodes are challenging to self-administer and impede in-home care. Wearable dry electrodes are more practical; however, they show higher impedances than wet electrodes and are costly to customize. This work presents a fabrication method for rapidly producing low impedance, anatomically fit dry electrodes that do not require hydrogels. By using electroless copper and gold plating with 3D printing, biocompatible electrodes can be optimized for individuals at a fraction of the cost of existing vacuum deposition-based techniques. Example 3D dry electrodes made with this process are evaluated alongside clinical-standard devices in typical scenarios to compare electrical performance and comfort. The resulting dry electrodes exhibit an average electrode-skin impedance of 66.7 kΩ at 50 Hz and DC offset of −20 mV without any hydrogel, which, when area normalized, is within the range achieved by wet electrodes without skin abrasion.